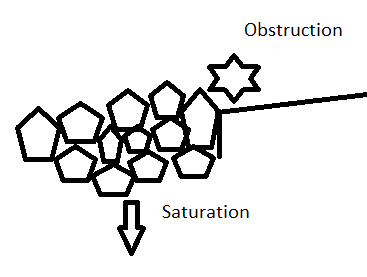

Well-constructed loose riprap beds with proper elevation, gradation, filter layer, and subgrade preparation are a good solution to erosion. But riprap beds have some problems. Because they are uneven both on top and bottom, they obstruct debris and water and they dry or drain slowly.

Obstruction

Obstructing debris and water as it leaves paved areas is usually unacceptable since it may significantly degrade longevity and change flow patterns.

- Water may pond and clog a pipe or accumulate sediment and deterioration on pavement.

- Water may bypass an inlet and arrive at an undesired destination.

- Water may go around a spillway instead of down it, causing new erosion.

Obstructing the outlets of small pipes and drains is also unacceptable since it leads to clogging.

Saturation

Draining slowly can cause subgrade saturation that leads to structural failure of walls and surfaces.

Proper elevation can solve obstruction. But proper elevation is rare to achieve in the real world even with careful specification and inspection. And it does not solve saturation.

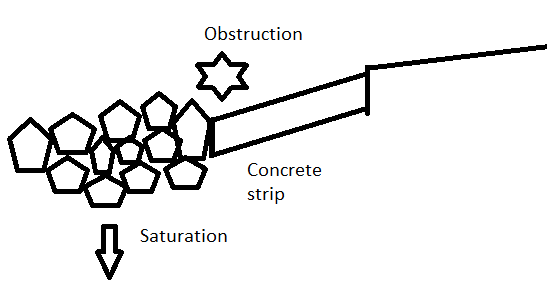

Solution: Concrete strips

A concrete strip at the top edge of the bed can solve obstruction and saturation. Specify a concrete strip as long as the top width of the bed and about 1ft to 2 ft (300mm to 600mm) wide sloping at least 8% and preferably 25% so that improperly high stones downstream of the concrete strip cannot obstruct the intended performance of the spillway inlet.

Related

Related note: One problem that cannot be solved with concrete is improperly high elevation where water leaves a riprap bed at the bottom of a spillway or outlet apron. These are locations where commonly a scour hole would naturally form until it reaches a depth and volume/mass that create momentum equilibrium between the mass of water in the hole and the velocity of the arriving falling water. Improperly high riprap elevation here has the undesired effect of moving the scour hole downstream of the riprap bed. A clearly communicated conceptual "lined preformed scour hole" approach in these locations is essential. Possibly specifications like the following may work: "Top of all stones at edge of bed shall be lower than adjacent grade" so that no additional drop occurs at the end of a riprap apron.

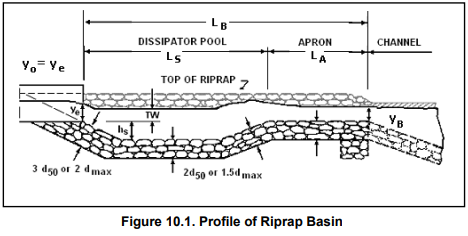

The FHWA Riprap Basin (H.E.C. #14 Chapter 10) is a standard design similar to a lined scour hole.

|

| FHWS Riprap Basin flowing left to right |

No comments:

Post a Comment